Automatic Tank Welding

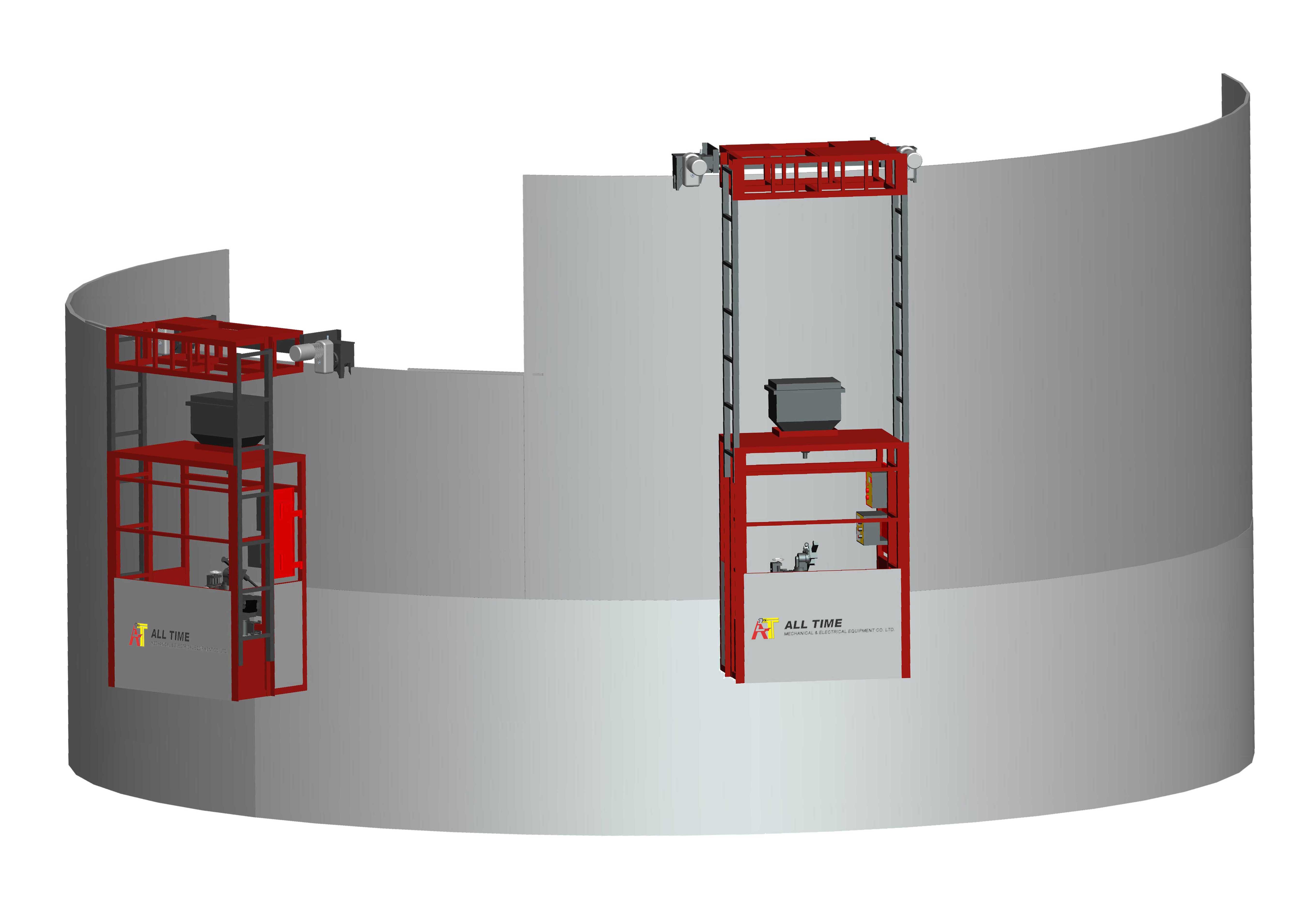

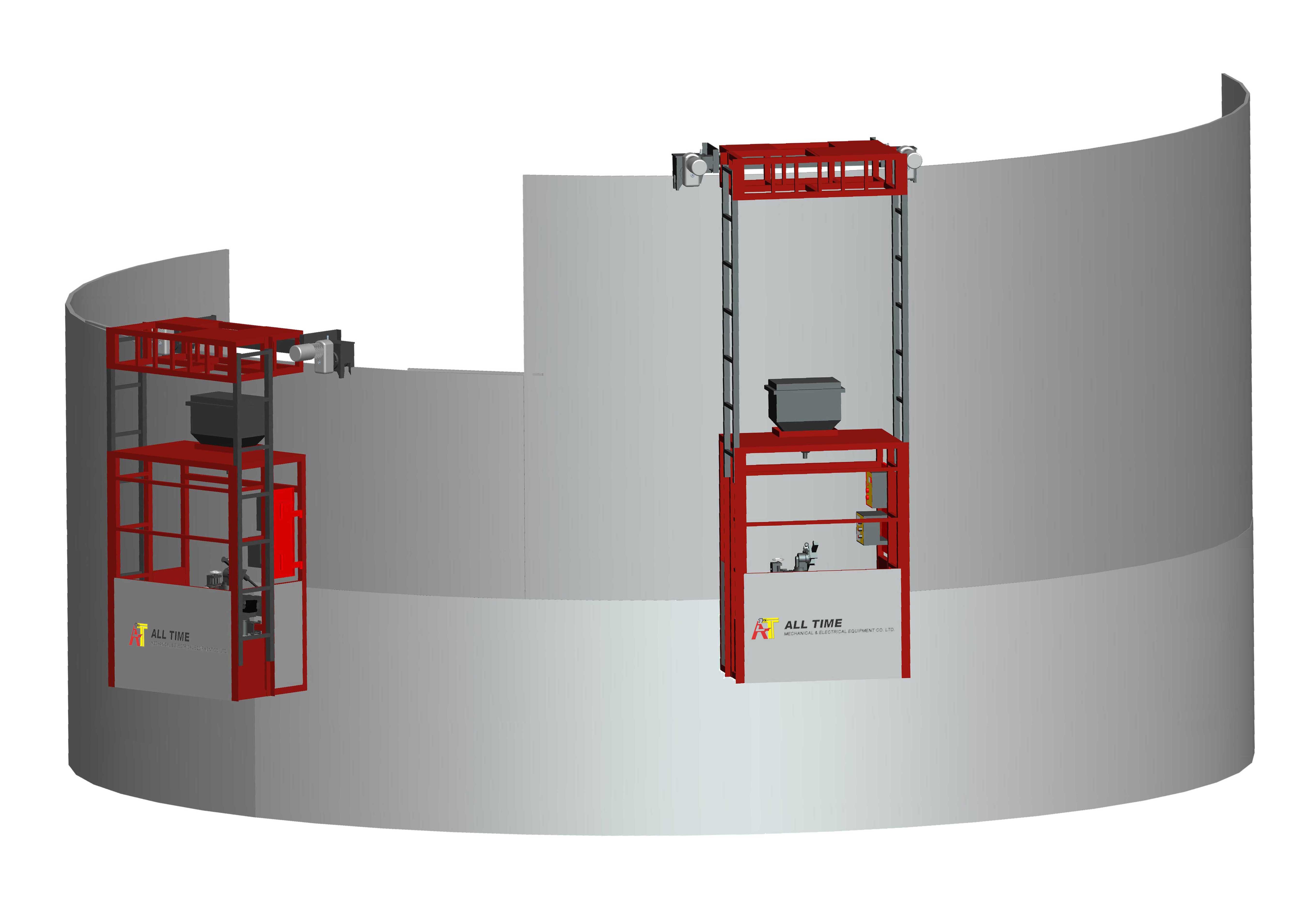

Automatic Girth Welder (AGW)

|

|

The All Time Automatic Girth Welder (AGW) is an automatic equipment applied to reduce the welding time for joining tank courses during field erection.

Each is equipped with welding heads, travel control, flux belt and recovery system so that horizontal (3 & 6' clock direction) can welded.

It straddles the shell plates riding on adjustable flanged wheels, travels at a controlled speed for mechanized SAW.Basic components that make up an AGW are machine frame, welding head(s), controls, flux support belt(s), flux recovery units(s), welding power supply with storage case.

|

|

|

|

Advantages

Horizontal seam welded by AGW

|

|

1. Utilize mechanized SAW process to weld storage tank horizontal seams 20 times faster than traditional manual welding processes.

2. Power propelling frame & operator platform allows welder to perform various welding operations in different tank courses with comfort.

3. Provides high quality continuous weld seams around the tank circumference.

|

|

|

|

Equipment

All Time provides four models of AGW for various types of tank configurations.

AGW1 - for single sided horizontal girth inside / outside welding of large storage tanks with SAW.

AGWII - for double sided horizontal girth inside / outside welding.

AGW LNG – special version of girth welder for double shell cryogenic tanks (e.g. 9%Ni LNG tank)

AGW1D –girth welder with special modular frame for both "Traditional" AND "Jack up" storage tanks welding.

AGW Control with digital speed display, travel speed potentiometer, direction switch, weld / rapid travel control, power on/off, flux lift winch ,flux vacuum on/off and emergency stop. Also connected to the Lincoln welding control for sequencing.

|

|

|

|

Technical Data

|

- Diameter: 4.5 m and up

- Welding wall Thickness: 8 ~45 mm

- Plate width (height): 1.8 – 3.2 m

- Capacity: 2.2 – 4.5 m ("LNG" model only)

|

|

|

|

|

|

| Field Applications |

- Welding Duplex Stainless Steel Tower

- Steel mill blast Furnaces Welding (80 mm heavy wall / double bevel)

- Simultaneous tank ID/OD horizontal welding

- "Jack Up" tanks welding

- LNG inside 9% LNG tank

- 9%Ni tank

|

|

| Welding Duplex Stainless Steel Tower |

All Time AGW1 Welding Duplex Stainless Steel Tower

Steel mill blast Furnaces Welding

Steel mill blast Furnaces Welding with All Time AGW1 & EGW (80 mm heavy wall / double bevel)

Simultaneous tank ID/OD horizontal welding

All Time AGWII Double sided girth welder for simultaneous tank ID/OD horizontal welding

"Jack Up" tanks welding

AGW-I/D welding "Jack Up" tanks

LNG inside 9% LNG tank

|

AGW-LNG frame is designed to allow operation within the clearance between the inner and outer tank shells (eg. 9% Ni LNG tank)

|

All Time AGWII – LNG Outside 9% LNG tank

All Time AGWII – LNG Inside 9% LNG tank

9%Ni tank

165,000 m3 9%Ni tank Work Site

|